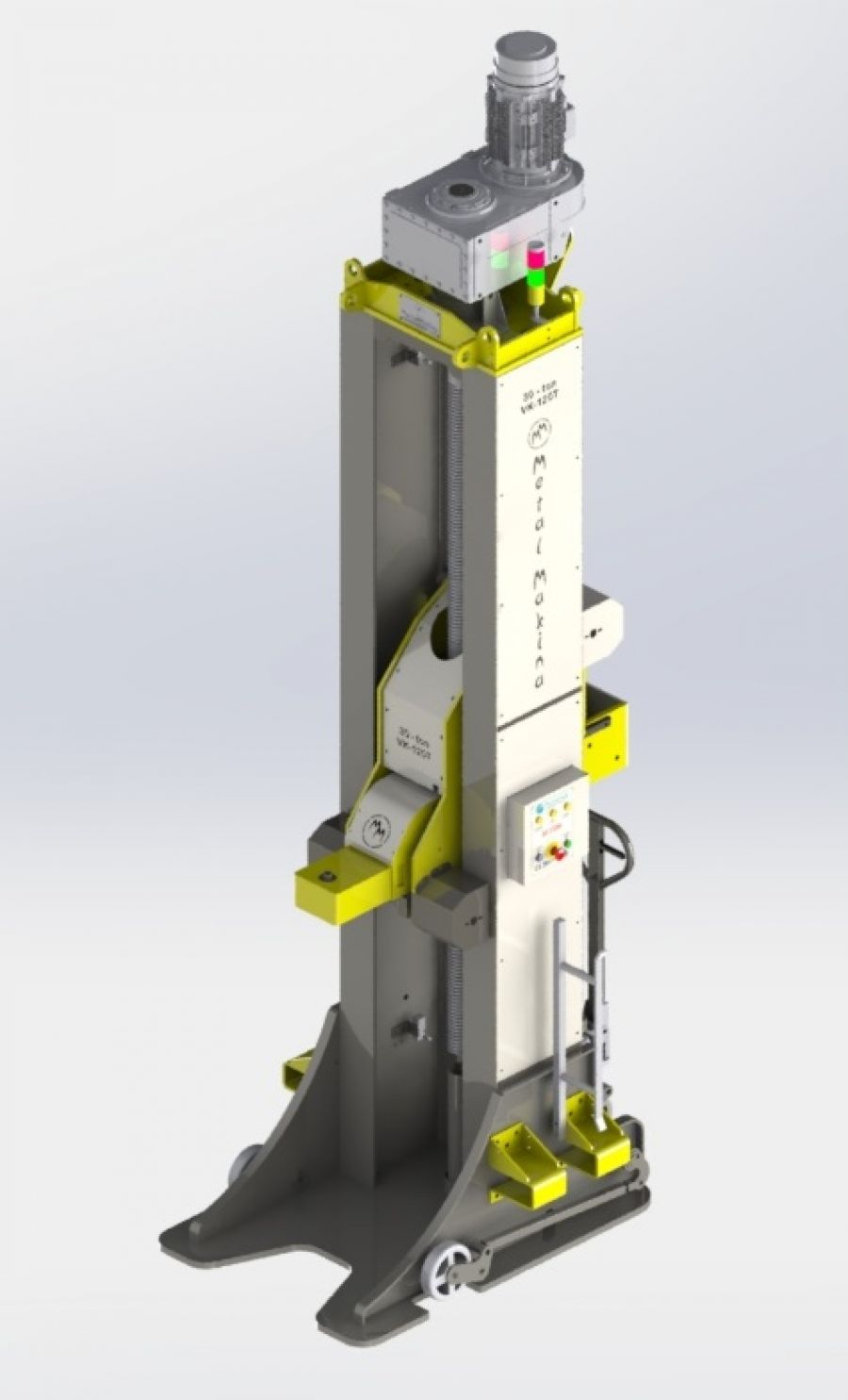

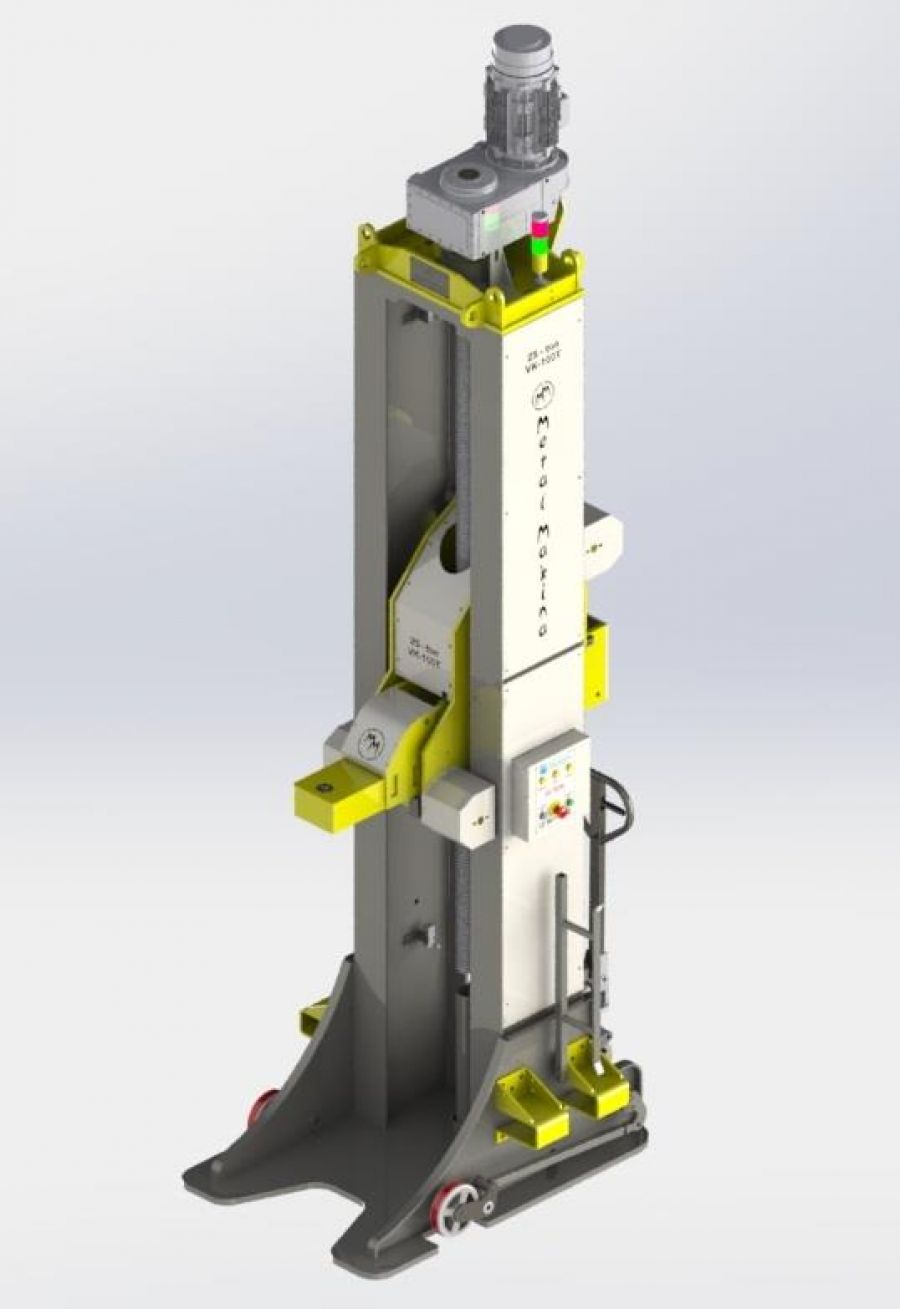

VK160T 160 TONS WAGON LIFTING JACK

- Home

- Wagon Lifting Jacks

- VK160T 160 TONS WAGON LIFTING JACK

vk160t-160-tons-wagon-lifting-jack

Click To Close

VK160T 160 TONS WAGON LIFTING JACK

VK160T will take its place among the fixtures of your business

Get Offer

1 Set Lifting Jack consists of 4 lifting jacks with a capacity of 40 tons and 1 main control panel. There is a control panel on each of the jack legs, and the first manual movement and load support movement can be made through these panels.

The lifting points of the jacks are adjustable back and forth, so that you can easily reach different lifting points of the loads you will lift.

Lifting jacks can be moved to the desired point along the rail line by means of electric motor driven side wheels on the rail tracks laid on the ground.

Thanks to the carrying rings on the top plate of the Lifting Jacks, the jacks can be easily moved from one place to another.

Safety measures in the VK160T Jack;

Height Limit Conditions: There are lower (minimum) and upper (maximum) limit switches on each jack, and each of these switches is positioned as two. In case of not detecting any of the limit switches, the backup switch is activated.

Obstacle at the Bottom: If there is any object under the body or lifting point during the lowering process of the jacks, these switches activate and the movement automatically stops.

Failure Status of Carrier Nut: It is activated in case of a possible malfunction of the carrier nut on the jacks and in this case the operator cannot continue the lifting process. The malfunction can be seen on the PLC screen. In case of damage to the main nut, the safety nut under the carrier nut takes the load and allows the suspended load to be lowered safely.

There is 1 safety nut on each jack stand, apart from the main carrier nut.

Fixed Position of Jack (Station): One of the factors that ensure safe lifting and lowering of jacks is the floor on which the base of the jack will sit. Care should be taken to ensure that the ground on which jack lifting will be performed is smooth and solid. In cases where the jack is not fully seated on the floor, this switch will activate and will not allow the operator to move.

Load Control status: Each of the Jack legs is controlled separately in a single working position to ensure that the jacks come into contact with the load safely. As soon as the lifting point touches the load, this switch exits single use thanks to the control switch to the main control panel, allowing the movement to be controlled synchronously from a single center.

Jack Movement Control: During the group operation of the jacks under load, the jack movement is instantly measured by the main control panel, thanks to the motion-sensing eyes placed on each jack, and the user can see these values on the screen. If there are differences between these values, which are constantly subject to control, the system values will go to equalization. This will work in the same way if one of the lifting point is somehow unloaded

You can use the METALMAK VK160T lifting jacks in binary groups or in quad sets

| MODEL | VK160T |

| ENERGY SUPPLY | 380 Volt AC / 50 Hz |

| SINGLE JACK MAX LIFTING LOAD | 40 TON |

| TOTAL MAXIMUM LIFTING LOAD | 160 TON / 4 PIECES |

| LIFT-DOWN SYSTEM | ELECTROMECHANICS |

| MOVEMENT TYPE | THREADED ROD-NUT TYPE |

| MOTOR POWER | 11 KW (WITH BRAKE) |

| WORKING TIME | PERMANENT |

| MINIMUM LIFTING HEIGHT | 500 MM (customizable value) |

| MAKSİMUM KALDIRMA YÜKSEKLİĞİ | 2500 MM (customizable value) |

| LIFTING SPEED | 250-300 mm / min (customizable value) |

| LIFTING POINTS TYPE | MOVING (customizable value) |

| LIFTING POINTS ADJUSTMENT DISTANCE | 450 MM |

| LIFTING POINT WIDTH | 310 MM |

| SAFETY NUT | AVAILABLE |

| THREADED ROD ENCLOSURE BELLOWS | AVAILABLE |

| MAIN CONTROL BOARD | AVAILABLE |

| CONTROL BOARD ON LIFTING JACKS | AVAILABLE |

| POWER CABLES | AVAILABLE (customizable value) |

| SYNCHRONOUS OPERATION BETWEEN JACKS (balanced lift) |

AVAILABLE |

| NUMBER OF SAFETY SWITCHES | 9 |

| HEIGHT LIMIT SWITCHES | AVAILABLE |

| MOVEMENT OF JACKS ON THE FLOOR | LATERAL MOVEMENT ON THE CARRIER MOVEMENT RAIL |

| JACK ROUTING ON FLOOR | HYDRAULIC TRANSPALET STYLE |

| PAİNT | ELECTROSTATIC POWDER COATING |

| LOCAL SETUP | AVAILABLE |

| ON-SITE OPERATOR TRAINING | AVAILABLE |

| GUARANTEE | 2 YEARS |

| SPARE PARTS SUPPLY GUARANTEE | 10 YEARS |

Contact us

"Always the Best"

Cumartesi: 08.00 - 16.00

Pazar: Kapalı